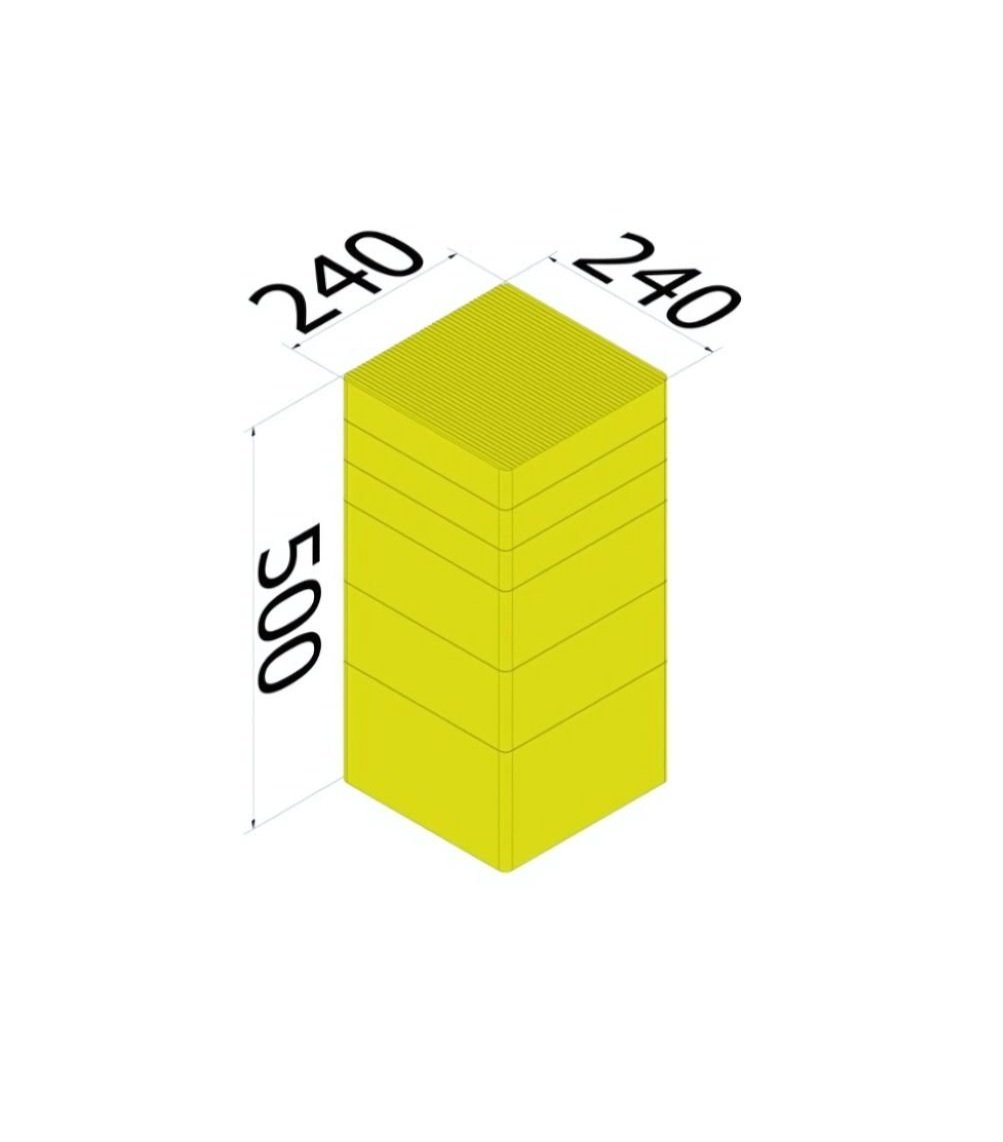

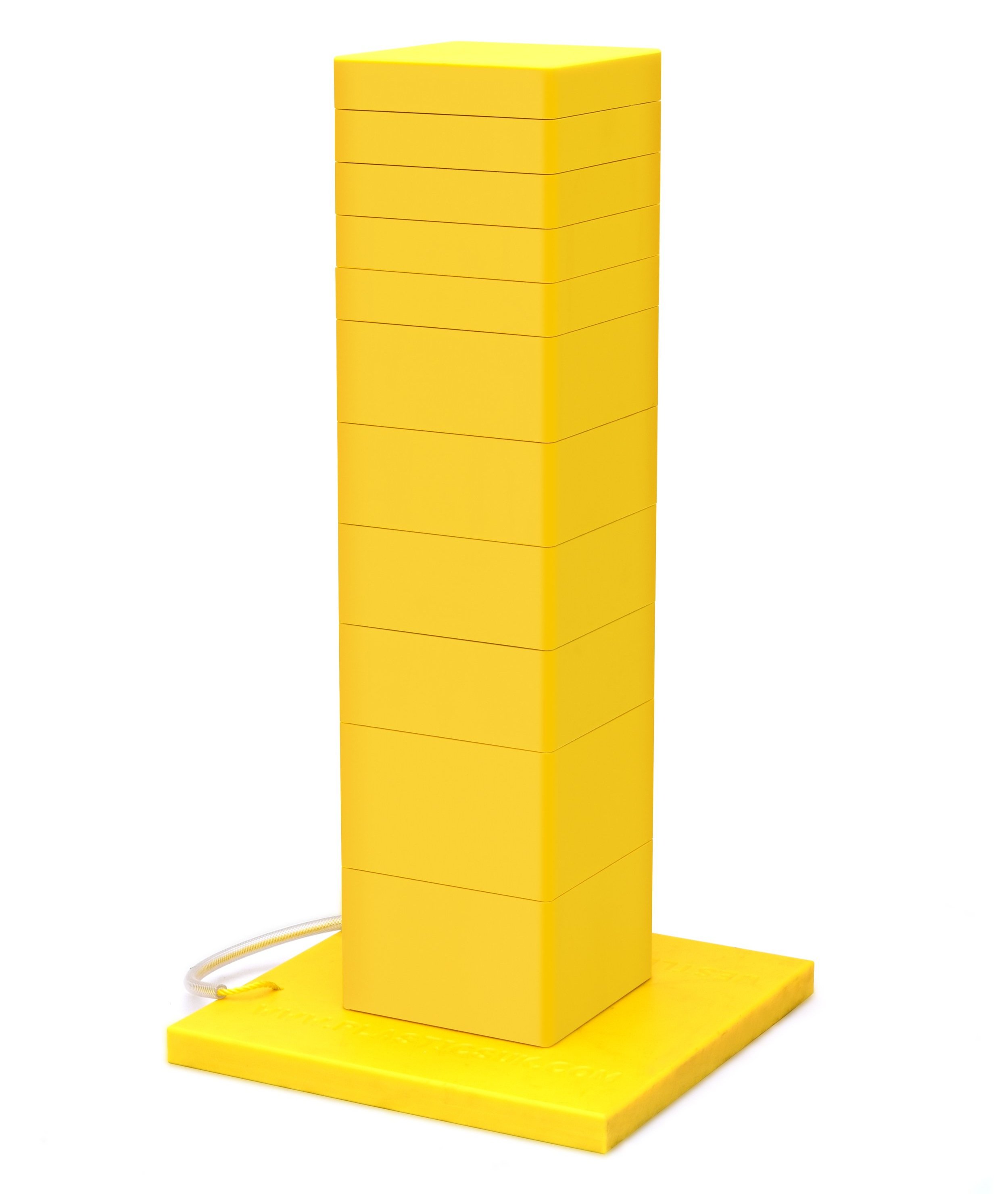

Cribbing Blocks

Westley Plastics manufacture Cribbing Blocks in the UK, designed to replace traditionally used timber supports with a high integrity load tested alternative.

Recommended by Safequarry, our blocks have been tested to 200T, making our cribbing blocks the safest way to block, jack and support machinery during maintenance. Timber supports are untested and can crack, rot or split meaning working underneath a vehicle supported in this way can be dangerous and potentially fatal.

Due to its interlocking design, the locks can be easily adjusted to the desired height and the whole system is lightweight, meaning it can be installed and removed quickly without a crane or forklift.

Reasons to choose our blocks:

-

The tough, high impact material has been designed specifically for the use of cribbing, jacking and supporting quarry vehicles, heavy machinery, trains, trams, cranes and even temporary buildings.

-

Due to its interlocking design, the blocks can be easily adjusted to the desired height and the whole system is lightweight, meaning it can be installed and removed quickly without a crane or forklift.

-

Flexible heights and a variety of bespoke caps (axle V, jack stand, rubber caps) making the system adapatable to a variety of applications, whilst still retaning its load rating certification. Company names can also be engraved on request

-

Timber supports are untested and can crack. rot or solit. meaning working underneath a vehicle supported in this way can be dangerous and potentially fatal. In contrast, our cribbing blocks have been tested to 200 tonnes; ensuring workers are sate whilst giving peace of mind to health and safety officers and managers.

-

Proudly manufactured in the UK, with worldwide shipping available to bring our products to you, no matter where you are based.

All our blocks can also be ordered by email or phone. Contact us today for more information about your order and any special requests including special engraving, bespoke tops and different sizes.